Home / Load dumpers / Pallet turners

Pallet turners

Change of pallet for its transport or to carry out a different process within the handling or production of the load.

PALLET TURNERS

Technical sheet

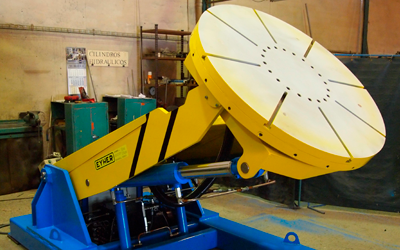

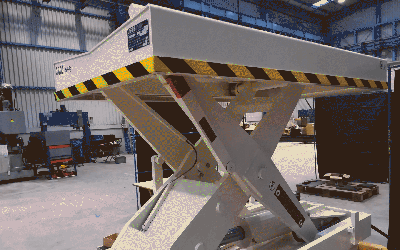

Structure: 12mm thick sheet metal flame-cutting structure.

Drive: drive by motor-reducer-brake with torque limiter, sprockets and chain.

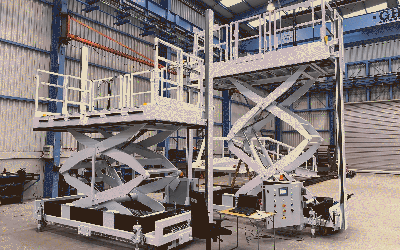

Fixing: fixing of the load during dumping by a system of four retractable hydraulic lashings and a system of 1 to 3 scissor tables actuated by an electro-hydraulic group with cylinders, electric motor (IP-55), pump, tank, solenoid valves, piloted non-returns , etc.

Stops: front and rear defense stops to prevent the turner from hitting the load during its introduction.

Electrical control: electrical control according to EN 60204-1 in a cabinet with a main switch that can be locked with a padlock. Start and stop buttons. Magnetothermic circuit breaker, etc. With retained signal type operating pushbuttons and emergency stop pushbutton. With support for fixing on the ground.

Operating modes: electric maneuver with 2 operating modes by key selector; manual and automatic.

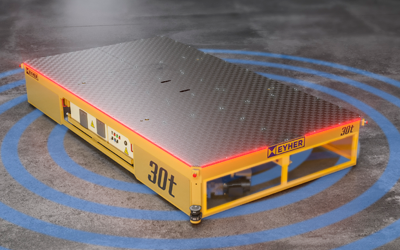

Others: hole to facilitate the access of the nails of the LGVs.

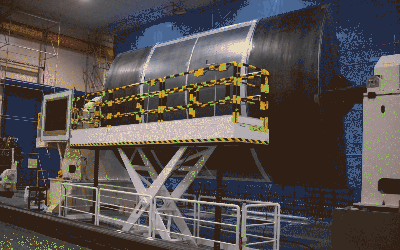

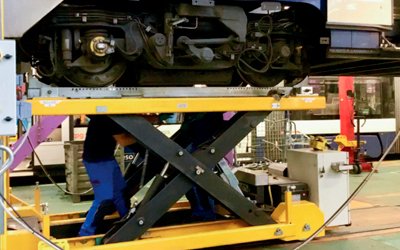

At Eyher we specify, design and manufacture turners for changing pallets in industrial processes where the load is required to be turned over to change an origin pallet (pallet with which the load is transported, for example) to a destination pallet (pallet with which a process is going to be carried out with the charge, such as a heat treatment or a press charge for example) .

Pallet turning machinery

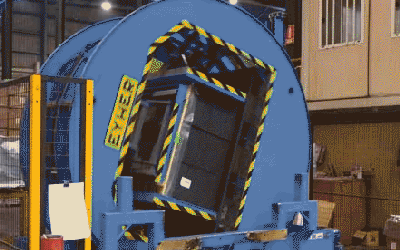

EYHER pallet turners allow the load to be flipped, being conveniently secured by controlled pressure, and, having previously placed the original pallet on top, after turning 180º, the load will rest on the pallet with which is required to carry out the next operation in the process that is being carried out with said load.

Customized pallet turners

Eyher offers capabilities for the specification, design, manufacture and installation of custom-made pallet turners , as well as personalized post-sale service according to the needs of each client, based on its extensive multi-sector experience, but where the applications are repeated and the knowledge after 65 years. of history can be taken advantage of.